Factory Tour

Premium Flooring Manufacturer

SPC Flooring Manufacturers is a high-tech enterprise focusing on the research and development, production and sales of Stone Plastic Composite flooring. We have advanced production equipment and a complete testing system with strong technical force. The company adheres to the business philosophy of “quality first, service first, reputation-based”, and is committed to providing high-quality, environmentally friendly and innovative flooring to global customers.

In terms of production and manufacturing, SPC Flooring Manufacturers has significant advantages. We have introduced internationally advanced stone plastic floor production lines and adopted automated and intelligent production methods, which greatly improved production efficiency and product quality. At the same time, we pay attention to the selection and control of raw materials, and have established long-term and stable cooperative relations with many high-quality suppliers at home and abroad. Each batch of raw materials meets international environmental standards and company requirements.

In terms of technical research and development, we have an experienced and innovative R&D team. They continue to explore new technologies and processes, and are committed to developing more environmentally friendly, wear-resistant, non-slip and easy-to-clean stone plastic floor products. Through continuous research and development and innovation, our products have covered a variety of styles, colors and textures, which can meet different needs for home decoration and commercial usage.

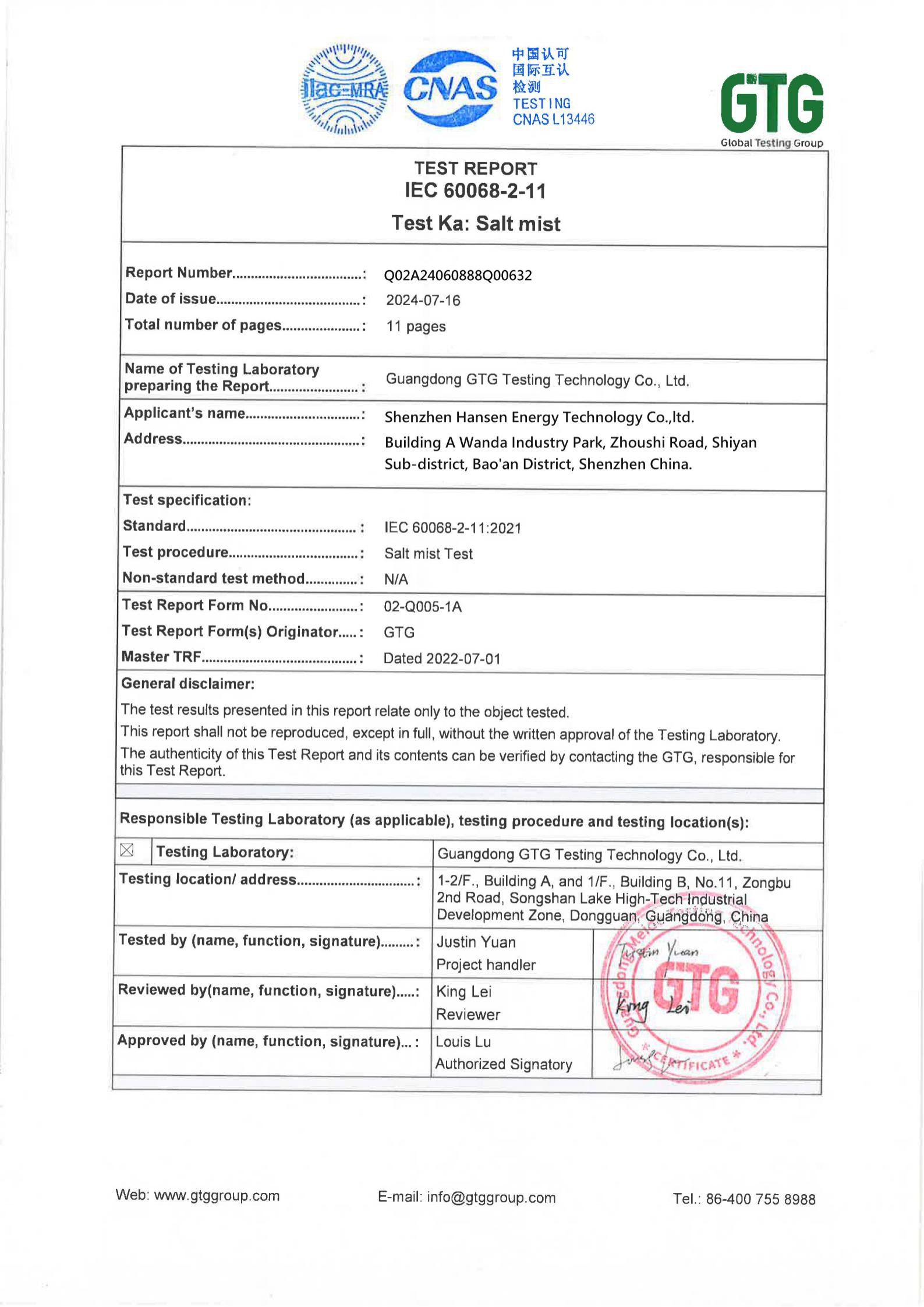

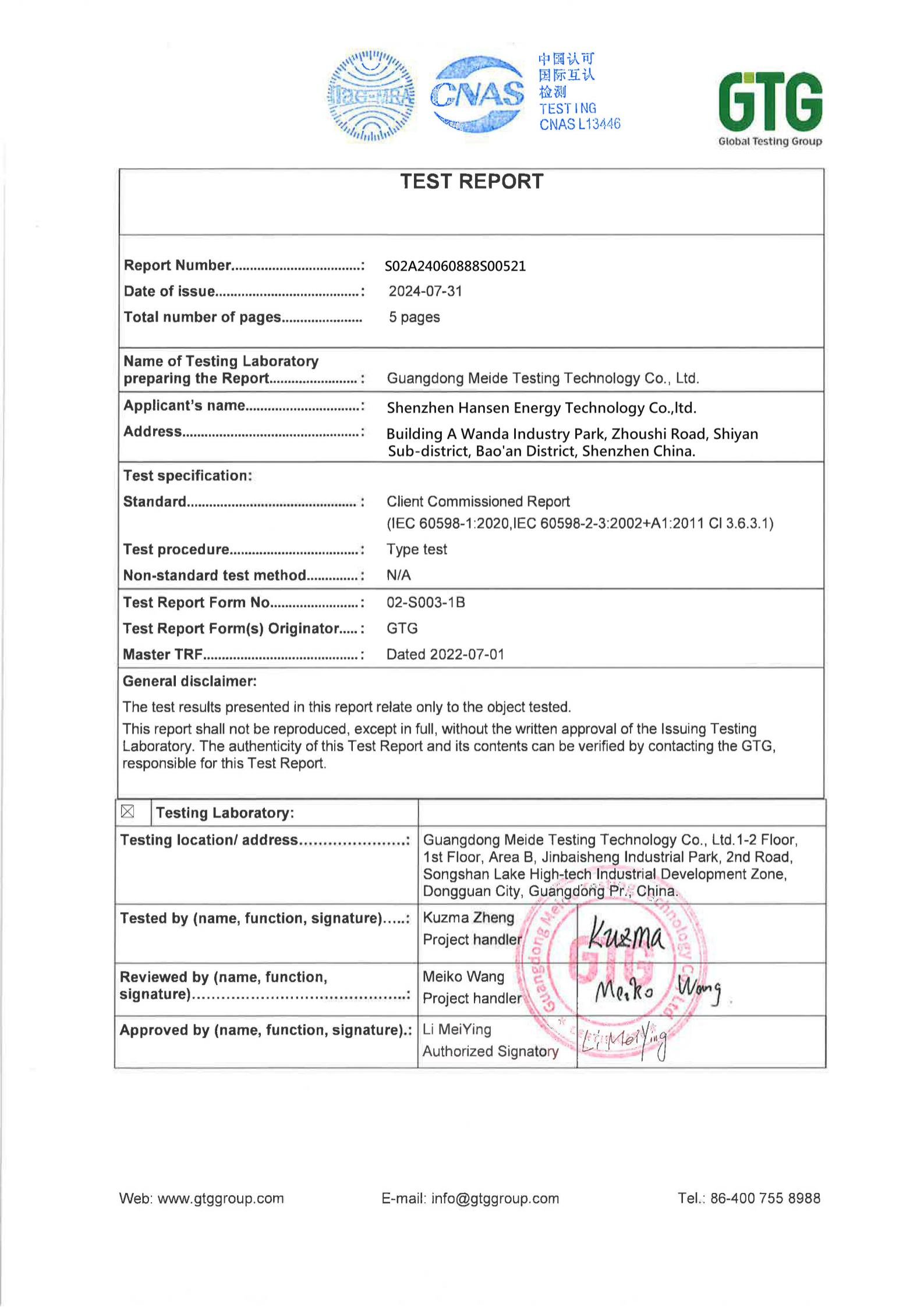

In order to ensure product quality, we have established a strict quality control system. From the storage of raw materials, the production process to the delivery of finished products, every link has been strictly tested and screened.

In recent years, our products have been sold to many regions at home and abroad, and are widely used in homes, offices, shopping malls, schools, hospitals and other places. With excellent product quality, high-quality after-sales service and honest business attitude, we have won the trust and praise of our customers.

In addition to focusing on product quality and service, we also pay great attention to environmental protection and sustainable development. Our SPC flooring are made of environmentally friendly materials, non-toxic and harmless, recyclable, and meet international environmental standards and requirements. At the same time, we also actively participate in various environmental protection activities and public welfare undertakings, and are committed to contributing to the society.

Looking to the future, we will continue to adhere to the business philosophy of “quality first, service first, reputation-based”, continue to increase R&D investment and technological innovation, and launch more high-quality and environmentally friendly SPC flooring products. At the same time, we will also actively expand domestic and foreign markets, establish long-term and stable cooperative relationships with more customers, and jointly create a better future. We look forward to working with you to create brilliance together!

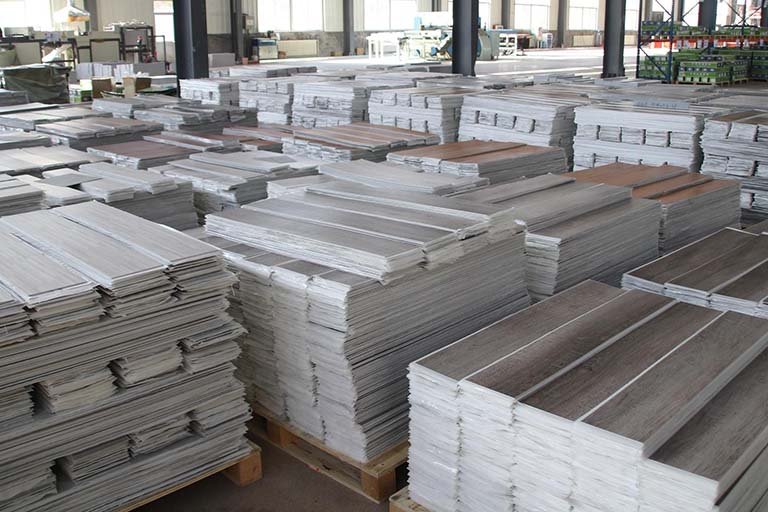

Workshops

Workshop 1

Workshop 2

Workshop 3

Workshop 4

Workshop 5

Workshop 6

Production Flow

Key production process in SPC flooring manufacturing

High speed mixing

The raw materials are automatically measured according to the raw material ratio and poured into the high-speed mixer for hot mixing and cold mixing.

Hot mixing can make the various materials mix evenly and remove the moisture in the materials; cold mixing is to cool the materials to prevent agglomeration and discoloration.

Extrusion

The mixed materials are added to the twin-screw extruder for heating and extrusion. The extruded sheet is passed through a four-roll calender to determine the thickness.

Then a color film and a wear-resistant layer are attached, and finally cooled and cut.

UV tempering

The extruded and cut floor panels are surface UV treated and then tempered to increase the hardness and wear resistance of the floor panels.

Slitting, slotting and packaging

The tempered floor is cut according to the rules, and then it is formed by vertical and horizontal slotting equipment, and finally fully or semi-automatically packaged.