OEM & ODM SPC Wood Flooring Service

We can provide personalized customization according to customer needs, including size, pattern, bottom material (IXPE/EVA), packaging and brand logo services to meet different market positioning and channel sales. We are committed to providing cost-effective and timely one-stop SPC flooring services to partners such as flooring brands, wholesalers, engineering companies, etc. If you are looking for a reliable OEM & ODM SPC flooring supplier, please contact us for samples and quotes.

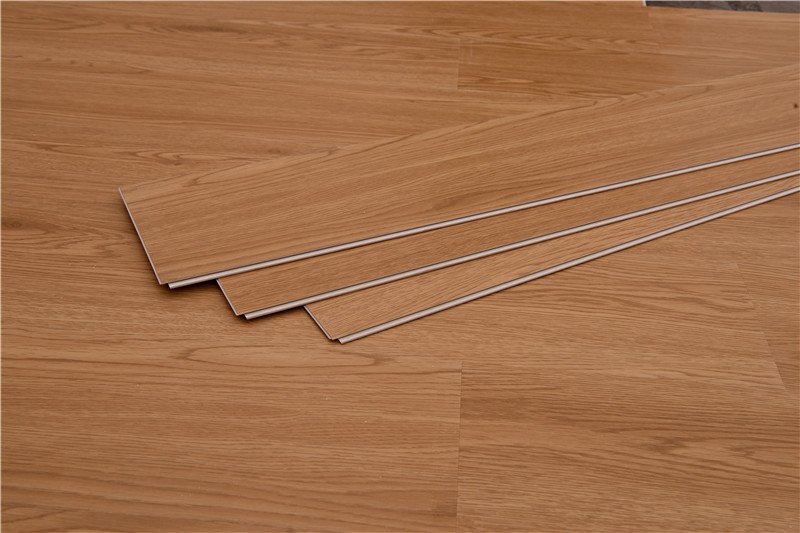

SPC Wood Flooring Products

SPC Herringbone Flooring

SPC Herringbone Flooring

SPC Herringbone Flooring

SPC Herringbone Flooring

SPC Herringbone Flooring

SPC Herringbone Flooring

SPC Wood Flooring Vs. Wood Flooring

| Comparison Aspect | SPC Click-Lock Flooring | Wood Flooring |

|---|---|---|

| Waterproof & Moisture Resistance | 100% waterproof; made from calcium carbonate + PVC. No swelling or warping in humid areas. | Only splash-resistant; real wood or MDF-based core can swell or deform easily in damp environments. |

| Durability & Lifespan | Highly wear-resistant with protective coating; lasts 10–20+ years, proven in commercial use. | Varies: solid wood is refinishable but prone to scratches; laminate is durable but less so than high-grade SPC. |

| Maintenance Cost | Low maintenance; simple dry or damp mop with neutral cleaner. No waxing or oiling required. | Higher maintenance; requires special cleaners and occasional waxing or board replacement. Sensitive to humidity. |

| Installation Ease | DIY-friendly click-lock system; no glue/nails. Fast, low-cost, can install over existing tiles. | Solid wood often needs nailing/glue. Engineered wood may allow clicking, but still more tools and time required. |

| Eco-Friendliness | Made from stone powder + PVC, formaldehyde-free. Many certified for indoor air quality. | Solid wood is eco-friendly, but composites may contain formaldehyde. Choose certified (E0/E1 or CARB) products. |

| Aesthetic & Comfort | Wide variety of wood/stone patterns. Firm underfoot, not cold like tile but less warm than wood. | Natural, warm, rich textures. Softer and more elastic; ideal for comfort in long standing. |

| Cost (Material + Labor) | Approx. $8–$20 USD/m2 → $1–$3 USD/m². Medium pricing, lower labor cost. | Solid wood: $30–$80 USD/m²; Engineered wood: $20–$40 USD/m². Labor costs extra ($1.4–$7 USD/m²). |

| Dimensional Stability | Highly stable; minimal thermal or humidity expansion. Needs only small expansion gap. | Less stable; expands/contracts with moisture/temperature. Needs careful gap and moisture control. |

SPC Wood Flooring Advantages

Green and Healthy, Worry-Free Living

Waterproof and Built to Last

Fast Heat Conduction, Ideal for Floor Heating

Moisture-Proof and Non-Slip Safety

Wear-Resistant and Long-Lasting

Natural Texture, Comfortable Touch

Easy to Install and Maintain

Quiet and Comfortable Living

Scratch-Resistant and Pet-Friendly

Factors affecting the SPC wood flooring price

Total thickness (4mm/5mm/6.5mm/8mm)

The greater the total thickness of the board, the more raw materials (stone powder, PVC) are used, and the unit cost is usually higher. Generally, the SPC wood flooring thickness is 4~8mm, and the thicker the board, the better the durability and sound insulation.

However, the thickness of the board is not the only factor that determines the price. Some studies have pointed out that the thickness of the wear-resistant layer is the key factor. Although too thick SPC boards are more durable, the installation height increases and the transportation cost increases, which is not a linear increase in price.

Wear-resistant layer thickness (0.2mm/0.3mm/0.5mm)

The wear-resistant layer is usually in the range of 0.2~0.7mm. The thicker the wear-resistant layer, the stronger the surface scratch resistance and wear resistance, and the longer the service life. For commercial spaces, we recommend you choose 0.5mm wear-resistant layer or more to cope with high traffic. The cost of thick wear-resistant layer SPC flooring is significantly higher than that of 0.20.3mm level.

0.3mm is a common threshold, and the qualified SPC flooring price will be more stable; the wear-resistant layer below 0.2mm has low cost, but is easy to wear. In short, the thickness of the wear-resistant layer directly affects the quality and price. The thick wear-resistant layer can increase the price.

Substrate density and filling ratio (stone powder to PVC ratio, honeycomb/full solid core)

The core of the SPC floor is made of calcium carbonate stone powder and PVC resin. When the proportion of stone powder is high, the unit raw material cost is low (stone powder is cheap), but the floor density is high, the weight increases, and the logistics cost rises. The high PVC content increases the raw material cost, and the floor is more flexible and impact-resistant. Different SPC manufacturers have different formulas, and the cost difference is significant.

Honeycomb (hollow) structural panels reduce material usage and weight, and the cost is relatively low, but the stability and strength are weaker than full solid core; full solid core panels use more materials and have higher costs, but are more durable. In general, high-density solid SPC floors use more materials and have higher costs; reducing the filling ratio can moderately reduce prices, but SPC manufacturers must take into account strength and durability.

Surface decorative film quality and printing process (HD imitation wood grain, multi-layer overprinting)

The surface decorative film determines the appearance fidelity and SPC flooring cost. High-quality imitation wood grain printed film and 4K HD multi-layer overprinting process can present realistic textures, but the printing consumables, precision requirements and equipment investment are higher, and the unit price is correspondingly increased.

Ordinary films only provide basic colors and are low in cost; while increasing the number of printing layers, using advanced inks and UV-proof topcoats can significantly improve the visual effect and weather resistance, while pushing up the unit cost.

Surface treatment (EIR synchronous pattern, UV coating, embossing type)

EIR synchronous texture: synchronous embossing (Embossed in Register) requires the embossing cam to match the printed wood grain accurately, the production process is complex, and the mold and technology requirements are high, so the cost is high.

UV coating/hardening layer: Adding a UV curing coating on the wear-resistant layer can improve hardness, anti-fouling and wear resistance, but it adds a production process and material cost.

Different embossing patterns (such as deep embossing, slight texture, relief texture, etc.) require different molds and embossing pressures, and the process investment varies. In short, higher-end surface treatment improves product performance and touch, but also increases the price accordingly.

Bottom layer structure (IXPE/EVA sound-absorbing pad, integrated foaming)

Common bottom layer structures include IXPE/EVA foam attachment layer, which is used for sound insulation and shock absorption and improves foot feel. SPC flooring with foam bottom layer is more expensive than products without bottom pad due to the complex materials and lamination process

Integrated foaming technology (integral PVC foaming) is different from conventional lamination, requires special equipment, and has high process difficulty. Although integrated foaming board may save the post-foaming process, equipment depreciation and process costs will also be reflected in the unit price.

Whether there is a bottom layer or not and what kind of shock-absorbing material is used will affect the unit cost. SPC flooring with attached bottom layer is usually more expensive.

Lock system design (ordinary lock/patented lock/easy to disassemble structure)

Ordinary lock structure is simple and has low production cost; SPC flooring with patented lock has higher manufacturing cost.

Easy-to-remove or reinforced locks require additional designs (such as reinforced tongues, etc.) to improve assembly and disassembly convenience and floor sealing, and also increase production processes. In short, the higher the end of the lock, the higher the unit cost is usually.

Functional additions (fire rating, anti-slip rating, antibacterial treatment, etc.)

Fire rating: For example, European standard Bfl‑s1 or domestic B1 SPC requires the addition of flame retardants and passes the test, and the cost of additives and testing fees will push up the price.

Anti-slip rating: By changing the surface texture or material formula to obtain a higher anti-slip coefficient, it is usually necessary to add friction coating or special embossing, which will also increase the process cost.

Antibacterial treatment: For example, adding antibacterial agents such as silver ions or using an antibacterial layer requires additional raw materials and processing steps, which also increases the cost.

Other additional functions such as anti-fouling and UV protection, although they increase the added value of the product, all correspond to additional materials or process inputs, thereby raising the unit price.

Certification and testing (CE, FloorScore, SGS, anti-formaldehyde, etc.)

SPC floors for the international market often require certifications such as CE mark (Europe), FloorScore (US low volatility certification), SGS testing, and domestic E0/E1 formaldehyde standards.

Some certifications (such as floor combustion level testing, VOC testing, etc.) have long cycles and high costs. SPC manufacturers usually spread the certification costs into the product selling price, so if the floor obtains more certifications, it often means a higher price. Although uncertified products have low costs, they are limited by market access.

MOQ and OEM/ODM Service

SPC suppliers usually require higher MOQ to ensure production economy. Large-volume orders can dilute fixed costs such as molds, equipment, and management, so the price per piece will decrease. In other words, the more you order, the greater the wholesale discount the supplier offers.

Conversely, when the unit cost is high for small batches or sample orders, SPC suppliers often increase the unit price or charge additional fees.

Customized SPC flooring requires initial investment in mold development, pattern design, exclusive packaging materials, etc., especially when complex customization requirements increase costs. If the order volume is not enough to share these development costs, the unit price will be significantly higher than the standard model.

In summary, the above technical parameters and service requirements will affect the unit price of wood SPC flooring to varying degrees.

SPC Wood Flooring Application

SPC Flooring For Family Home

SPC Flooring For Commercial Office

Durable Home SPC flooring

SPC Wood Flooring FAQs

How is the wear resistance of SPC wood flooring? Compared with solid wood, laminate flooring or ceramic tile?

Is wood SPC flooring waterproof and moisture-proof? Can it be used in bathrooms and kitchens?

SPC stone plastic flooring is mainly made of PVC and stone powder, wich has excellent waterproof and moisture-proof properties. Its base material will not expand and deform due to moisture, so it is suitable for humid environments such as floor heating and kitchens. In contrast, solid wood and ordinary laminate flooring easily absorb moisture and expand and warp when exposed to water. It should be noted that the SPC floor surface is relatively smooth and it is easy to slip when it encounters water. Therefore, we usually do not recommend it for bathroom floors. It can be used in local wet places such as kitchens, but it is best to use anti-slip mats or choose SPC floors with anti-slip textures. In general, SPC is worse than wooden floors in waterproof performance and close to tiles, but it is not as good as anti-slip tiles in terms of wet safety.

Is SPC wooden floor environmentally friendly and safe? Will it release formaldehyde?

SPC wood floor is mainly composed of inorganic materials such as PVC resin and calcium carbonate. It does not contain harmful substances such as adhesives and formaldehyde. It usually meets indoor environmental protection standards and is a relatively environmentally friendly floor material. In contrast, some solid wood composite boards or laminate floors use glue on the substrate and joints, which may release trace amounts of formaldehyde; tiles and natural stones themselves do not contain formaldehyde and are also environmentally friendly materials. In general, as a type of PVC plastic floor, SPC flooring has almost zero formaldehyde release, making it more reliable to use.

Is SPC flooring difficult to install? How does it compare with solid wood, tiles, etc.?

SPC floor usually adopts snap-on assembly design, without pouring glue. When installing, just splice the floor locks together and leave appropriate expansion joints, which is fast and time-saving. In contrast, solid wood flooring needs to be nailed or glued and expansion joints are left, which is more complicated to construct; ceramic tile installation requires cement mortar base and polishing; although laminate flooring is also snap-on, wood SPC flooring can be laid directly on cement or old ground, just need to ensure that the base is flat. Overall, SPC flooring is easy to install and has low labor costs, which is very suitable for quick decoration or DIY.

Is SPC flooring comfortable to walk on? How is it compared to wood flooring or LVT?

SPC wood flooring has a harder base material, and it feels hard and slightly cooler on the feet, giving people a stone-like touch. In comparison, solid wood flooring feels warm and soft on the feet, not cold in winter, and WPC wood-plastic flooring with foam core feels the best on the feet; ordinary LVT flooring is also slightly elastic due to PVC material, and the foot feel is between the two. Ceramic tile feels the hardest and coldest on the feet. It should be noted that if used with floor heating, SPC wood flooring can also conduct heat quickly, but in the absence of floor heating, the foot feel is indeed not as comfortable as wooden floors.

Is SPC flooring easy to take care of? Is it troublesome to maintain?

There is a wear-resistant layer on the surface of SPC flooring. General stains can be cleaned with an ordinary mop, You do not need waxing or special care. Because its material is hard and wear-resistant, dust and oil will not easily penetrate. Usually, it only needs to be wet or dry mopped regularly to restore the smoothness. But please avoid using high-temperature steam mops or strong acid and alkali cleaners to avoid damaging the wear-resistant layer. In general, SPC wood floors have low maintenance costs and are easier than solid wood or laminate floors; compared with tiles, it has no gaps and will not accumulate dust, but the floor surface still needs to be cleaned frequently.

How long is the service life of SPC floors?

The service life of high-quality SPC wood floors can usually reach 15 to 20 years, or even longer. The SPC wood flooring life depends on the quality of the material and the environment in which it is used. If you buy branded products and install them correctly, SPC floors are stable, resistant to pressure and collision, and not easy to deform or break; while inferior floors may have problems such as broken slots or warping within a few years. In general, SPC floors are more durable than ordinary laminate floors, and have a service life comparable to high-end laminate or low-end tiles, but their hardness also requires a flat base when paved, otherwise long-term use may also affect their service life.

Is SPC wood flooring expensive? How is the cost-effectiveness?

The SPC flooring price varies depending on the brand, thickness and pattern, which is generally mid-range. Compared with high-end solid wood floors, SPC wood floors cost much less; compared with ordinary laminate flooring, the price is slightly higher. According to market references, the SPC wood flooring price per square meter is about US$10-20 per square meter, while high-quality solid wood floors of the same size are more expensive. From the perspective of comprehensive cost-effectiveness, SPC floors have the advantages of durability, waterproofness, and easy installation. Although the unit price is slightly higher than the cheapest laminate flooring, the long-term use cost is low, and it is a cost-effective alternative to wood grain flooring.

What places are SPC floors suitable for? Can it be laid in the bathroom?

SPC flooring is completely waterproof and moisture-resistant flooring. They can generally be used for indoor floors such as living rooms, bedrooms, kitchens and garages. Because its surface is smooth and easy to become slippery when exposed to water, we do not recommend it for bathroom floors (anti-slip tiles are recommended for bathrooms); it is also best to use waterproof floor tiles or PVC membranes in the shower area. It is more common to use SPC in the kitchen, just pay attention to the flatness of the floor and anti-slip measures. In general, SPC flooring is suitable for dry or occasionally humid indoor environments. It should be carefully selected in places such as bathrooms where wet and slippery requirements are high.

What is the difference between SPC flooring and LVT, WPC and other floors?

LVT and SPC flooring are both PVC plastic floors, and their main components are PVC resin and stone powder, with similar waterproof performance. However, the SPC floor substrate contains a higher proportion of stone powder and stabilizer. The board is harder, more stable, and has stronger pressure and collision resistance; LVT flooring is usually thinner and more flexible, with a slightly better foot feel, and is mostly paved or self-adhesive during construction. WPC wood plastic flooring adds foaming agent to the base material, making the floor lighter and softer to the foot. In general, SPC flooring is known for its stability and durability. It is suitable for occasions that require wear resistance and pressure resistance; LVT/WPC feels softer to the foot. It is suitable for places that require a higher foot feel or require thin boards to be laid.